Exploring the Unique Conditions of Underwater Refinement and the Synthesis of History and Modernity

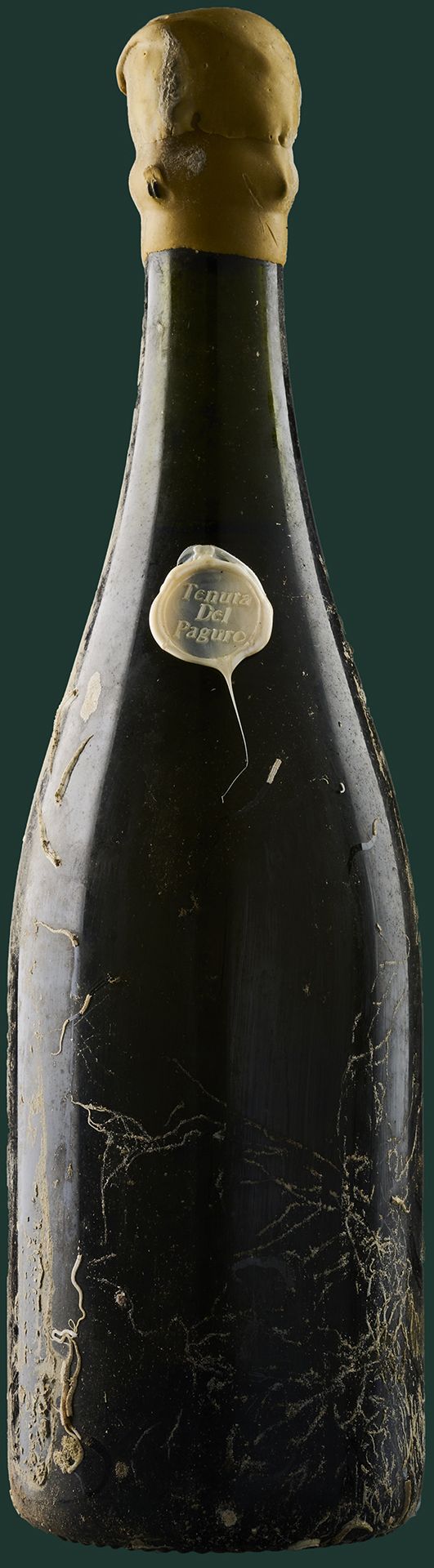

Tenuta del Paguro is the first winery in the world with a continuous record of underwater wine maturation. The first sparkling wine from Tenuta Del Paguro has emerged, our savoir faire finds its best expression in a classic method sparkling wine from the 2012 harvest in a unique and limited edition, fewer than 300 bottles were immersed, and a part of those that emerged were destined for scientific laboratories for research on the underwater refinement method. The wine was disgorged in June 2021.

It is the synthesis of the meeting between the history of yesterday, that of the ancient Romans, and today's story. The meeting between the hills of our land and our sea. At 30m deep, the wine is subjected to unique physical conditions: the absence of light protects it from UV rays, while the isobar maintains a constant temperature of 10–13°C. Some of these physical, natural factors can be reproduced in a traditional cellar, while others cannot be replicated, such as the harmonic swaying of sea currents and the pressure difference of 3 atmospheres between bottling and refinement. The results emerging from the collaboration with the University of Florence reveal significant evolutions in colour, smell and taste, without compromising the progression of the wine over time. The estate follows a philosophy of integrated agriculture with low environmental impact, for which it is certified. In 1965 the Paguro methane platform, caught fire due to a drilling error, sinking into the abyss. Over time, hermit crabs, scorpion fish and lobsters began to inhabit it, transforming it into an artificial reef which, in 1995, was declared a natural protected area.

Promoting Eco-Friendly Practices and Reducing Environmental Footprint Through Underwater Refinement

Tenuta del Paguro chose the place as a dive site in 2008, promoting respect for the area and guaranteeing a very low environmental impact. Underwater refinement brings further ecological benefits: almost zero energy requirement, thanks to natural refrigeration, and less warehouse space, reducing land consumption. Each bottle is sanitised, covered with a biodegradable film and equipped with a collar where the authenticity code is recorded by hand, making it possible to know the path of each bottle.